How to Navigate Supply Chain Challenges and Maximize Supplier Performance

Global supply chain disruptions — including escalating geopolitical tensions, severe weather events and economic pressures, as well as post-pandemic shortages — continue to impact organizations worldwide.

Significant inflation and interest rate increases have contributed to slowing demand. Timely availability of materials have impacted production build and fulfillment to customers. Extended end-to-end lead times and communication delays put business at risk.

To combat these challenges, successful organizations have had to evolve their relationships with suppliers and maximize performance within supply chains.

In our work with many top organizations, we’ve found the most effective ways to source and develop suppliers — ultimately helping our clients overcome these post-pandemic challenges and enhance customer satisfaction.

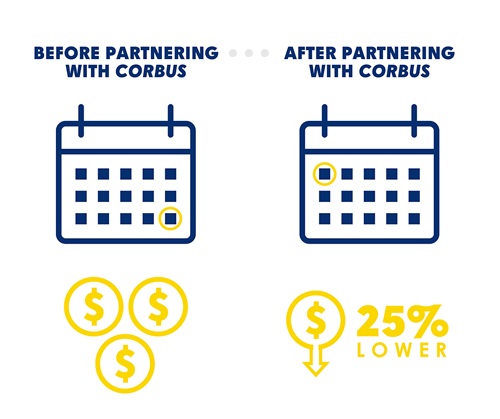

The numbers are proof: We’ve historically driven 20-30% delivery improvement with approximately 25% cost savings for our clients.

Here’s an overview of our two-pronged, outcome-driven approach — one that we can help you execute within your own organization.

1. Strategic sourcing and supplier development

Developing alternative suppliers — while also increasing communication and collaboration — is key for mitigating risk, reducing costs and improving on-time delivery.

We understand the importance of supplier development in navigating supply chain challenges post-pandemic and have assisted clients in developing strong supplier relationships.

- Our experts are uniquely qualified in vetting suppliers on a global and local level.

- We can help identify supply chain gaps and constraints, build relationships and drive business improvement.

- Using a data-driven approach, we evaluate supplier candidates across a number of crucial factors, customized to your needs and goals.

- Once a new supplier is selected, we assemble a cross-functional team to be onsite at the supplier’s facility and provide strategic solutions.

2. Constraint solving and performance improvement

Developing additional suppliers is an important way to improve quality, on-time delivery and capacity improvement. But how do you maximize supplier performance?

At Corbus, we know that supplier collaboration is the key to improving delivery performance. Our team collaborates extensively with suppliers to understand their needs and provide support. We look for the root causes of issues and clear roadblocks in a way that builds trust, aligns the team, and promotes performance.

Corbus’s approach focuses on collaboration to drive process control rigor, constraint solving and best practice sharing. We use transformative tools, including:

- On-site visits by a cross-functional team of supply chain experts

- Visual indicator metrics to keep the team aligned to process performance

- A detailed supply chain process map to determine improvement areas

- A root cause analysis to identify constraints and bottlenecks

- An extensive action plan with success criteria

Real-world results

Supply chain performance improvement is more than implementing a process — it’s about providing solutions and producing results.

For organizations facing post-pandemic challenges, supplier development will drive competition, resulting in improved quality, on-time delivery and capacity improvement.

And with the right strategies to maximize supplier performance, organizations like yours are able to streamline processes, improve flow and reduce costs. The goal is to enable a continuous improvement mindset.

With our expertise and collaborative approach, Corbus has developed a proven track record of driving value for our clients:

- ~70% improvement in material health visibility globally and across organization

- ~40% increase in supplier commits participation

- 20-30% improvement in on-time delivery to customers

To learn more about how supplier development can improve your organization’s supply chain performance, we encourage you to read our white paper Supply Chain Performance Improvement via Supplier Development, authored by Daniel Dickert, senior manager of Supply Chain and Transformation Services at Corbus.

Inside, you’ll also find real-world examples and successful case studies, including our work with a global fire suppression production manufacturer and a global aerospace client.

The white paper offers in-depth information on:

- How to navigate post-pandemic challenges that continue to stress supply chains and affect customer satisfaction

- Our data-informed approach to strategic sourcing and supplier development, customized to each client’s situation and goals

- Innovative strategies and transformative tools we use to address supplier challenges and provide strategic solutions that improve supply chain performance

- Real-world examples that demonstrate our proven track record of driving significant business impact